UFS 4.0 Protocol Analyzer

Product

Overview

Datasheet

Presentation

Application

Notes

PGY-UFS4.0-PA, UFS Protocol Analyzer is the industry-first working and tested UFS4.0 Protocol Analyzer. It offers protocol data capture and debugging of data across MPHY, UniPro, and UFS protocol layers. It allows for instantaneous decoding of UFS, UniPro, and MPHY layers with the flexibility to correlate decoded data across these protocol layers. PGY-UFS4.0-PA supports PWMG1 to HSG5B data rates and two TX, and two RX lane decode. The active probe has minimum electrical loading on the device under test (DUT) and captures protocol data without affecting the performance of DUT. PGY-UFS4.0- PA Protocol Analyzer supports two-lane data. Comprehensive on the fly decoding of UniPro & UFS data enables validation of communication between UFS host and device.

PGY-UFS4.0-PA Protocol Analyzer allows Design and Test Engineers to obtain deep insight into UFS host and device communication. MPHY/UniPRO/UFS packet-based triggering allows specific protocol data capture and analysis. PGY-UFS Protocol analyzer instantaneously provides decoding of UFS, UniPro, and MPHY layers with a correlation to MPHY, UniPro, and UFS layers.

I3C Electrical Validation Software Datasheet

Key features

- Supports electrical measurement for Fast, Fast plus, Push-Pull and Open Drain with limit comparison.

- Links the content to the electrical signal in the oscilloscope for easy understanding of the electrical characteristics of the protocol.

- Zooms the selected I3C packet content in the decode table in the waveform plot waveform window for easy analysis of electrical characteristics of the I3C frame.

- Detail view correlates physical layer waveform with I3C packet data.

- Utility features like zoom, undo, and fit screen for easy debugging while correlating the electrical data to the waveform.

- Ability to store the I3C electrical data in CSV and txt format.

- Report Generation

- Supports WFM file format for offline analysis

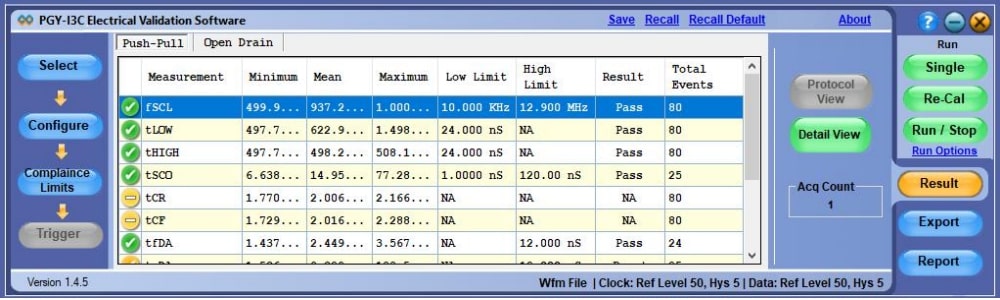

Now design and test engineers can automatically make accurate and reliable electrical measurements and decode protocols in PGY-I3C-EV software using data acquired by Tektronix DPO5000, TDS7000, DPO/DSA/MSO7000, MSO5/6 series oscilloscope to reduce the development and test cycle.

Seamless Integration with Oscilloscope

PGY-I3C-EV runs inside the Tektronix oscilloscopes and makes the electrical measurements, and displays the decoded data in a bus diagram, a table, and links the decoded data to electrical signal in the bus diagram.

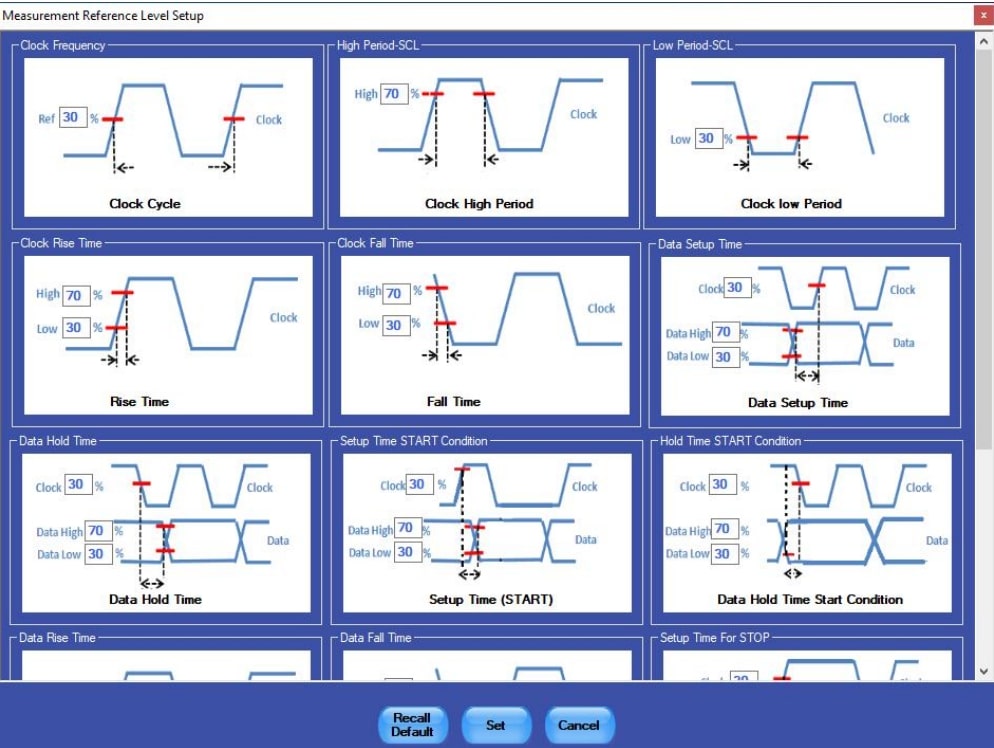

Reference Level Setup

PGY-I3C-EV is not just for standard electrical compliance testing, you can also vary the limits and test your device with custom limits. The intuitive limits and reference level setup allow you to configure the limits and reference levels for your custom testing needs. This enables you to test your device beyond the specification and characterize it.

Characteristics

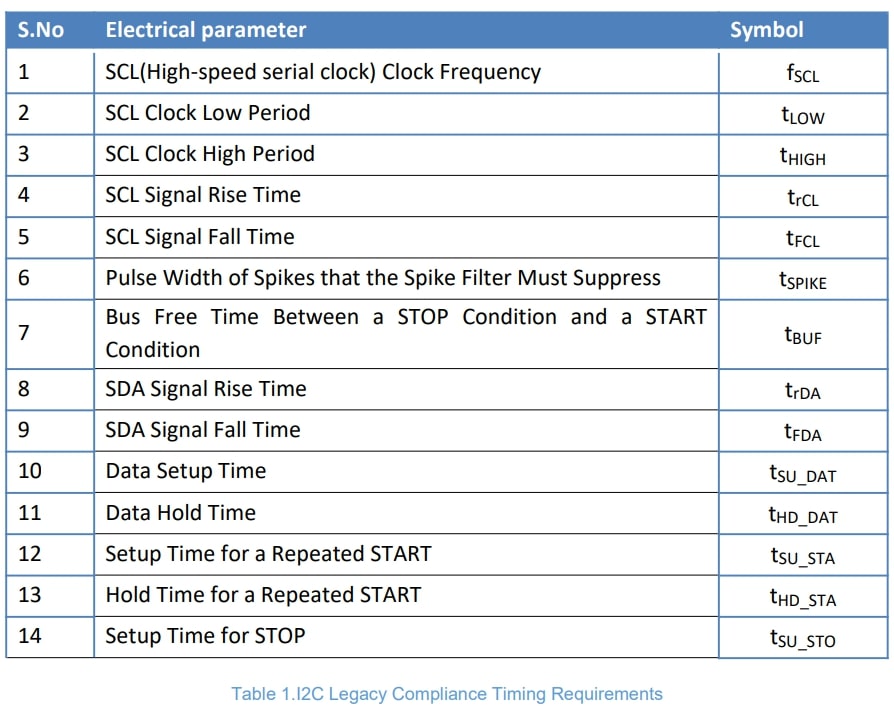

I3C Timing Requirements When Communicating With I2C Legacy Device

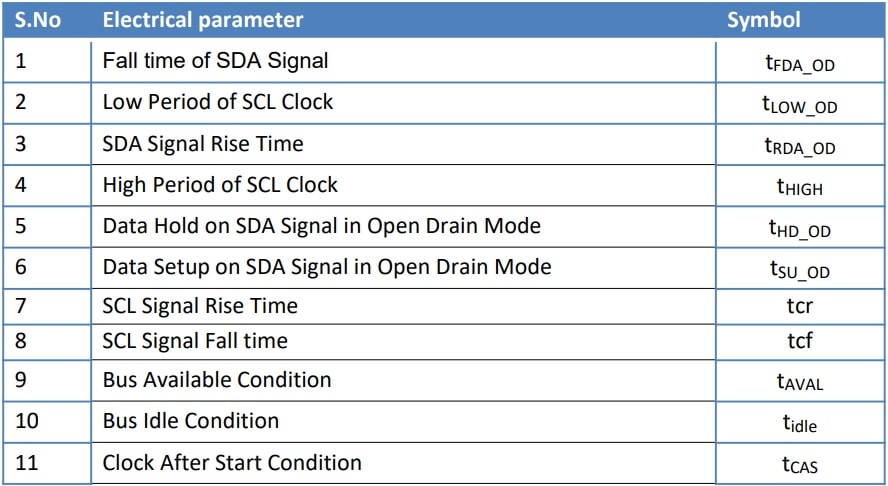

I3C Open Drain Timing Parameters

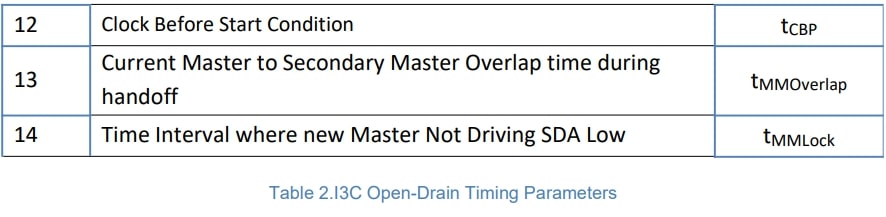

I3C Push-Pull Timing Parameters for SDR and HDR-DDR Modes

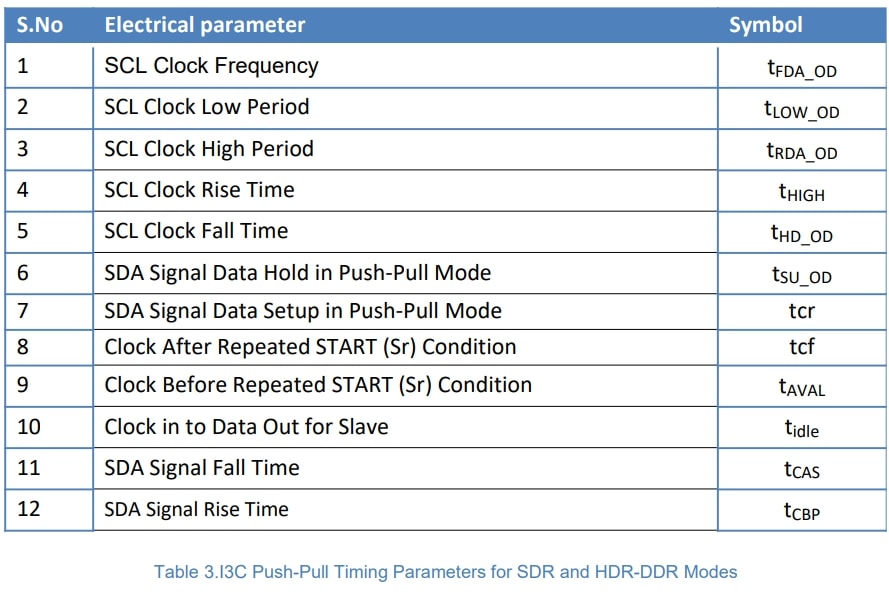

Powerful Debug Environment:

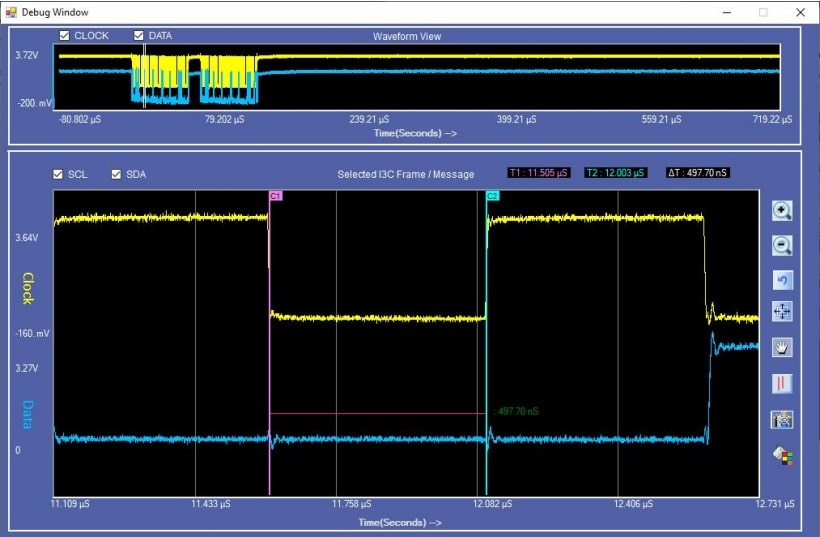

Debug Window

PGY-I3C-EV Software provides two types of debugging capabilities. In one of them, the worst-case result can be selected and linked directly to the waveform as shown here. The software provides the flexibility to define the number of acquisitions and the results will include worst-case results for all these acquisitions. The software can link the worst-case results to corresponding waveform acquisition using a simple right click of a mouse.

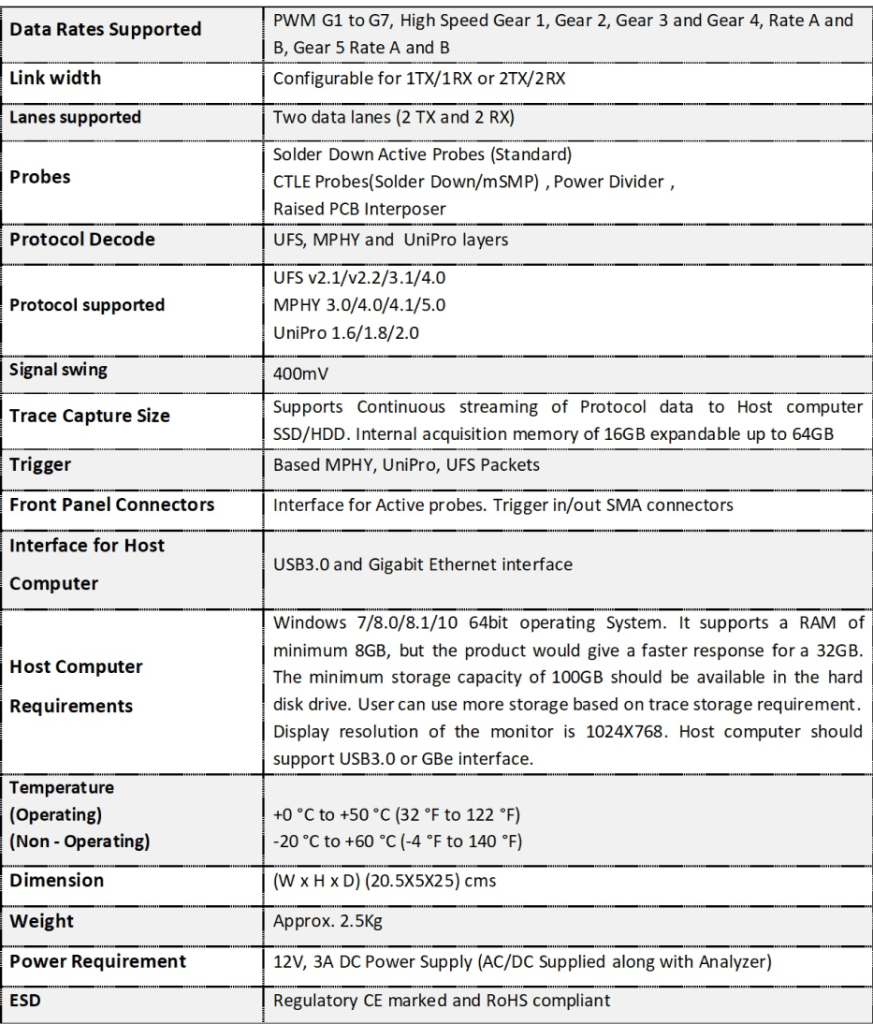

Key Specifications

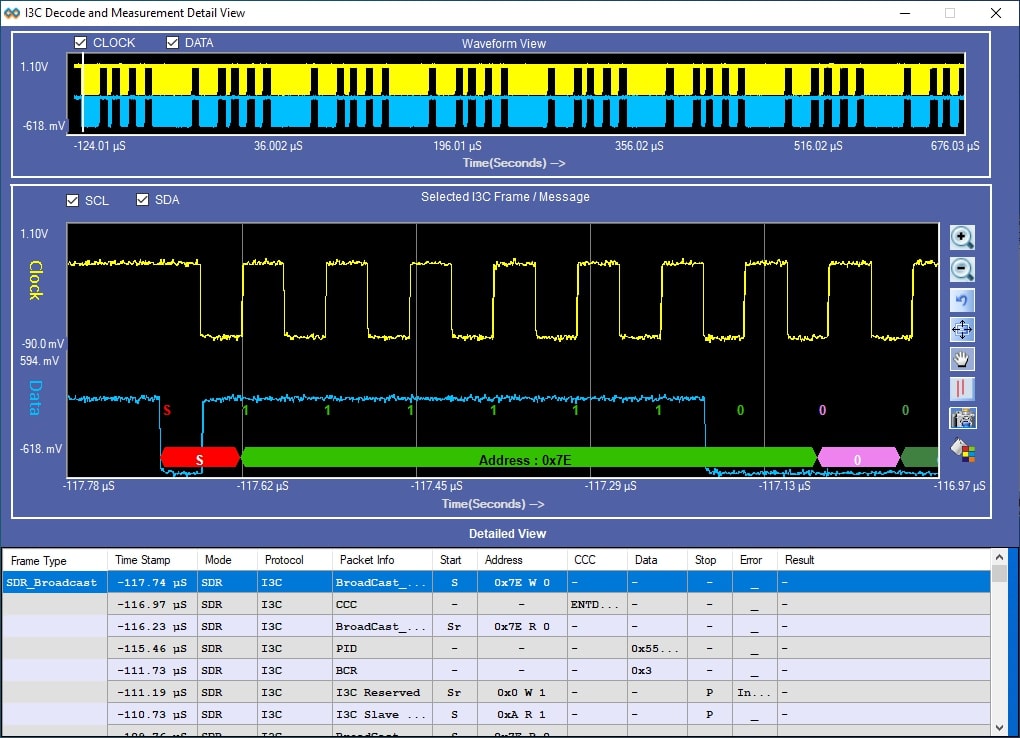

Detail view

In Detail View, engineers can view the analog waveform and details of electrical measurements in a single view. If there is any failure in electrical measurement, designers can quickly correlate with the analog waveforms. Users can select any row in the detail view; corresponding analog waveforms will be zoomed in and displayed. In the same row, engineers can view all the electrical measurements corresponding to the selected row. Utility features such as Zoom, cursors, and markers make custom measurements while debugging.